Product Specifications: Customized

Manufacturer: Coreballtech

Application Range:

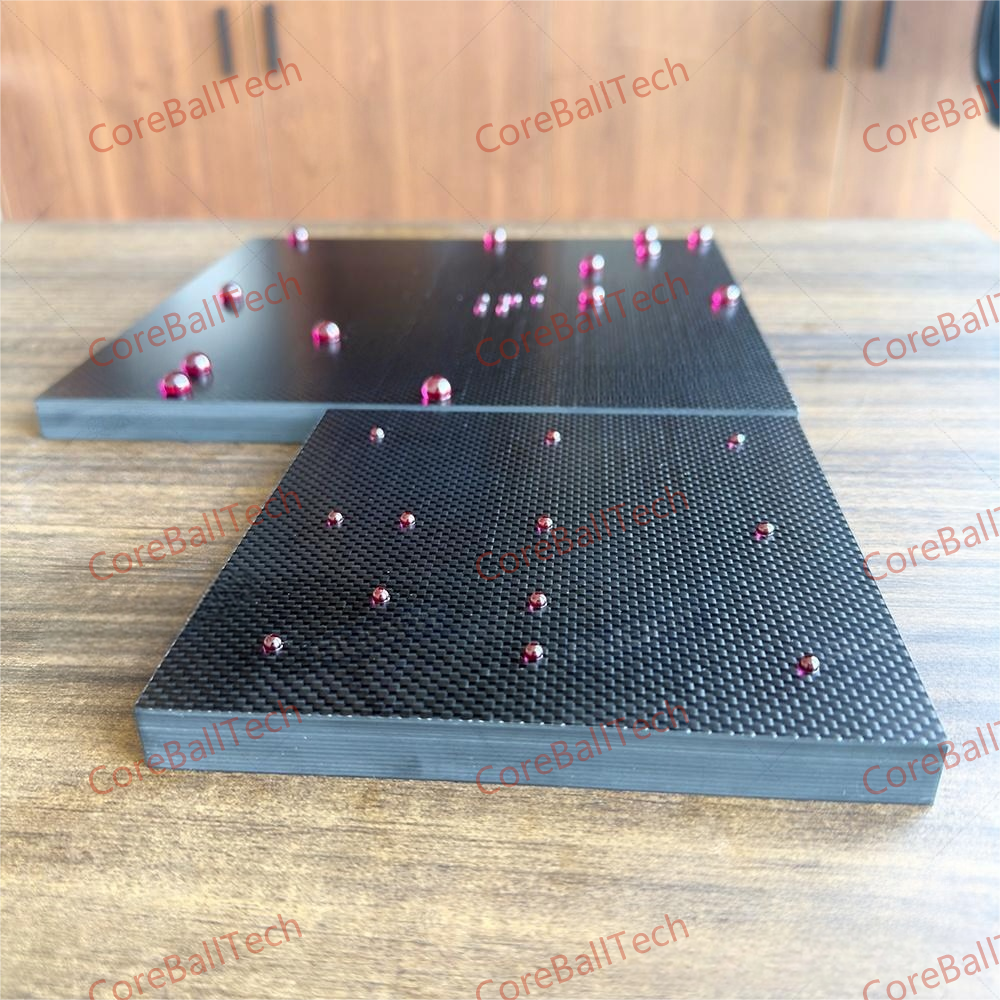

The 21-ball ruby calibration ball plate (Model: CBTQB001) from Coreballtech is widely used in X-ray CT inspection fields, offering exceptional accuracy and reliability. It has become an indispensable tool in various industries. The primary application areas include, but are not limited to:

Industrial CT

Measurement Technology (T)

Microscopic CT

Horizontal Spiral CT

X-ray Flat Panel CT

Accelerator CT

X-ray CT technology has found broad applications across many industries, especially in traditional sectors such as automotive manufacturing, electronics, casting, oil and gas exploration, geotechnical engineering, materials science, and biomedicine. Through high-precision 2D or 3D scanning, CT technology can accurately reveal the internal structure, material composition, and potential defects of the tested object.

The 21-ball ruby calibration ball plate offers a range of inspection solutions, including manual, semi-automatic, and fully automatic modes, significantly improving both work efficiency and inspection precision. It enables precise measurement of dimensions and geometric tolerances in hard-to-reach and hidden areas, making it particularly useful for composite material analysis, porosity analysis, wall thickness analysis, and reverse engineering applications.

Additionally, this calibration ball plate from Coreballtech effectively addresses challenges in high-precision inspection, such as dimensional, shape, and defect detection in biomedical materials, the nanotechnology industry, plastic engineering, aerospace, and automotive sectors. It supports high-precision 3D tomographic imaging, providing accurate analysis of internal structures and materials, and meets stringent inspection standards, making it an ideal choice for advanced industrial applications.